10% of Global greenhouse emission are caused by clothing and footwear production.

The U.S. EPA estimates that textile waste occupies nearly 5% of all landfill space. 200 Billions new items of clothing are made every year.

it matters, CAN HELP THE FASHION INDUSTRY TO RECYCLE EFFICIENTLY.

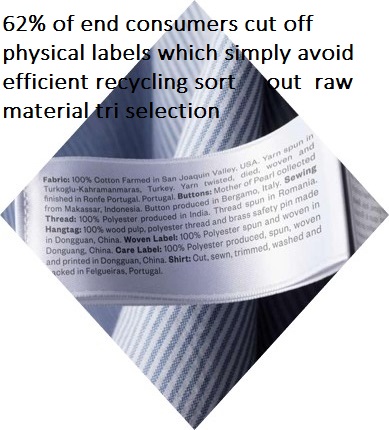

The amount of clothes bought per person has increased by 40 % in just a few decades, driven by a fall in prices and the increased speed with which fashion is delivered to consumers. The environmental impact is often felt in third countries, as most production takes place abroad. The production of raw materials, spinning them into fibres, weaving fabrics and dyeing require enormous amounts of water and chemicals, including pesticides for growing raw materials such as cotton. Consumer use also has a large environmental footprint due to the water, energy and chemicals used in washing, tumble drying and ironing, as well as to microplastics shed into the environment. Less than half of used clothes are collected for reuse or recycling when they are no longer needed, and only 1 % are recycled into new clothes. there is a need to support Textile recycle stakeholders in guaranteeing valuable textile components information at recycling stage, knowing that 74% of textile items got their labels cut-off by end consumers and 41% of 18 to 24 years population goes through internet to get cleaning advices (source Ipsos France and cofreet le Comité Français de l’Étiquetage pour l’Entretien des Textiles). Fashion brands would need to redefine a more sustainable strategy and communicate it in a call to action towars the end consumers.

Our long-lasting garments and footwear smart tag bring to Recycling factories raw material compositions This would lead to an automatized textile tri selection. Brands would be able to get back their recycling goods and become clearly circular engaged.

Imagine you could…

Activate each product with a digital identity…

Authenticate your Brand fashion item during the recycling phase at Recycling factories!

Organized in an automatized way each garment raw material component composition and increase massively Textile recycling

Amplify the buying experience of each customer with your product… !

Embrace sustainability and circularity strategy.

ENGAGE AWARENESS, TRACEABILITY AND TRUST

it matters is an end-to-end solution to optimize your company operation worldwide

with products-level visibility, protect brand integrity and to monitor your Brands A&F products at recycling stage.

HOW WE HELP THE FASHION INDUSTRY TO WIN THE RECYCLING GAME

Our smart tags are your Brand DNA

Each product has a unique digital identity

from RFID to NFC to GS1 digital link

we have developed long lasting tags resistant to washing ,dry cleaning and dryers with over 300 cycles and many more whether bi-techno or simple RFID&NFC suitable for each of your product (Garment & shoes)

Our cloud platform

You can monitor all data around the world in few seconds,in a dynamic way.Before it tooks weeks to gather one...

Everybody,

from any offices would be able to access and watch the same dashboard for proper anticipation and decision.

Product traceability

Which product? Which batch? Which vessel? Which port? Which country?Which city? Which stores? When? Whom?What time?Which channel

Not mentioning a powerful tool to help when it comes to reverse logistic and returning products...

Itmatters is the only company able to support Brands and raw material textile industry in identifying crops form the farm.

Thanks to our patented Taggant chemical D.N.A TRACER. invisible to the eyes,we are spraying a unique digital ID readable with itmatters mobilapp.

Your product

Authentication

At the recycling stage, our itmatters solution guarantees the identification of the brand of origin of the garments as well as the organization of the selective sorting of the materials of each garment. As we automatically process the material sorting of the garments, we record in the itmatters blockchain all the information related to each brand in terms of specific data on the volume of textile processed. All this information comes from our recycling partners. Since each product has a unique digital identifier, it is impossible to falsify the information.

RFID

We are working on standardized protocol with Recycling stakeholders and

major textile brands to implement an RFID protocol which will support Recycling factories to process in an automatized way the raw material components composition tri selection i.

Our technology will propel Fashion Brands in an end to end circularity program and a real call to action.

It is an affordable technology and can be implemented in emerging countries where the textile pollution is at stake.

Customer engagement

Our web app will provide according to each brand instructions , sustainability and others information about the product manufacturing country of origin, circular economy,... Also the activation of a second hand resale dash button would be an option to process on behalf of each customer the resale of their goods on a third party platform.

Our innovative technology is the only affordable solution to implement an automatized raw materials components tri selection in every recycling factories all over the world and collect back recycled raw material to be reused by brands . Reusing theirs own fibers would lead to increase the quality of raw materials at purchasing stage.